Lubricant for PVC, pigment dispersant, releasing agent for engineering plastics and toner

Hi-Wax™

Low molecular weight polyolefin

Applications detail

Applications

Characteristics

- Basic information

- Details of characteristics

- Details of applications

Overview

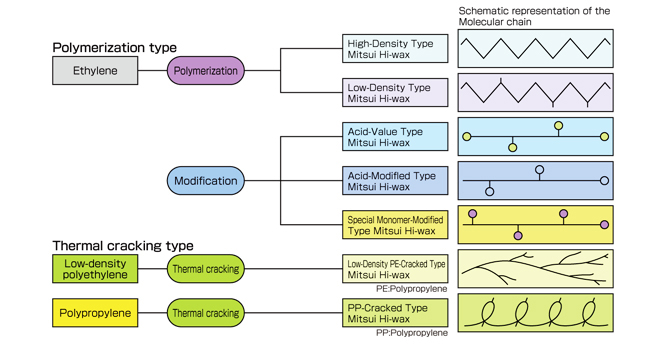

Hi-Wax comprises a low molecular weight polyethylene (PE) manufactured by direct polymerization, a technique developed by Mitsui Chemicals Inc. on the basis of Ziegler polymerization technology and low molecular weight polyolefin made by a thermal cracking process.

Hi-Wax is more stable in quality than other synthetic and natural waxes and a wide variety of grades are commercially available. So, these grades are being used for a broad range of applications, including those in high-technological areas such as toners for plain paper copying and film condensers as well as traditional uses inclusive pigment dispersants, slip agents and mold release agents for the molding of various synthetic resins, modifiers for printing ink and paints, aids for textile treatment, etc.

Each grade of Hi-Wax possesses distinguished characteristics which can effectively function by their proper use.

An assortment of various types of Hi-Wax: High-density polymerization type, low-density polymerization type, acid-value type, acid-modified type, special monomer-modified type, low-density PE-cracked type and PP-cracked type.

Along with properties such as releasability, viscosity adjustment, compatibility, slip properties and surface modification properties, more than 30 grades are opening up the possibilities of their use in new fields through proper use of these properties and grades.

Hi-Wax is very stable quality compared with that of natural and synthetic waxes, so that our wax is widely applicable to various uses in many areas.

What is wax?

- Solid / semisolid and brittle organic substance at room temperature.

- Low melting point (less than 150℃) and low melt viscosity.

- Crystalline and low molecular weight (300-10.000) resin.